Fuel tanks for commercial vehicles

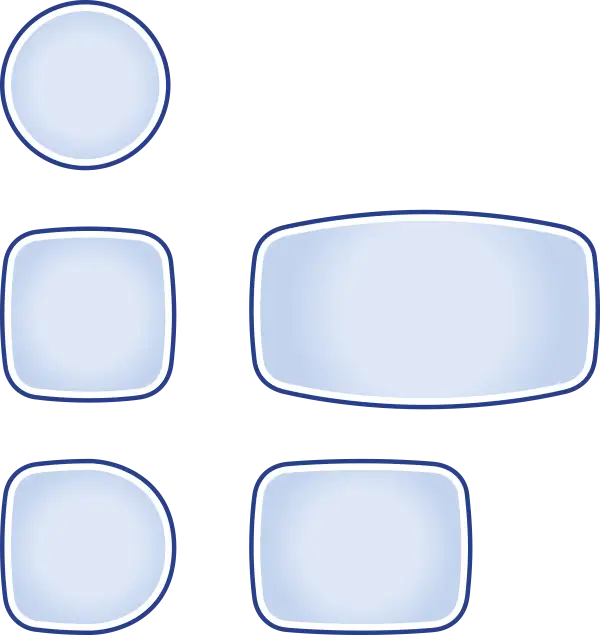

Flexible for many models and dimensions

The concept

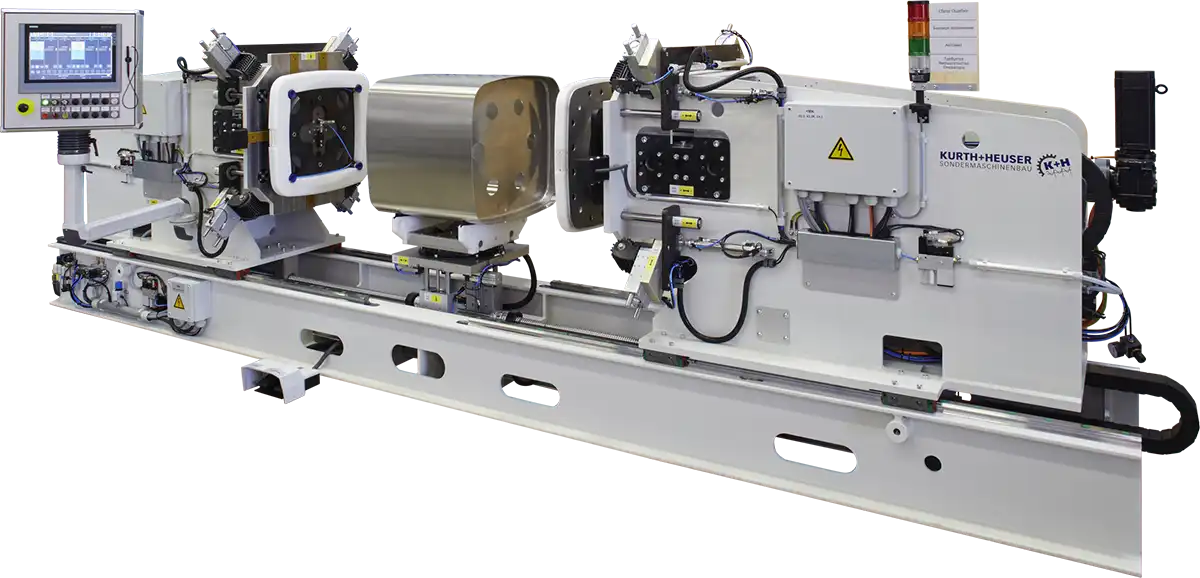

KURTH + HEUSER develops and manufactures high-performance stand-alone machines for all work steps as well as complete turn-key systems for the production of fuel tanks of any size for commercial vehicles. The production lines can be integrated by robotised transfer systems between the individual machines and are provided with all quality testing routines required. KURTH + HEUSER provides tank production lines from a single source. Fuel tanks of all major commercial vehicle brands such as DAF, IVECO, MAN, Mercedes, Scania and VOLVO are manufactured on K+H machines.

Highlights

- Just-in-Sequence-Production (JIS)

- Optimal surface quality

- Minimal setup times

Flexibility and quality

Production lines for fuel tanks are designed for batch or just-in-sequence (JIS) manufacturing: Large numbers of fuel tanks of various cross-sections and lengths are manufactured in any sequence required. The systems are changed over automatically and are ready to resume production within a very short period. Production systems from KURTH + HEUSER realise a great variety of processing modes including trimming, forming, punching and joining, assembly and testing with ultimate accuracy. Our key objective is to produce perfectly fitting components with tight tolerances throughout all intermediate steps. Fuel tanks can be manufactured from various materials such as aluminium, steel or stainless steel.

High system availability

KURTH + HEUSER systems are designed for a long service life and ultimate availability: Durable individual components, parts from renowned manufacturers, tools with long service lives as well as a customer service for regular maintenance and adjustments to new requirements.

Processing methods

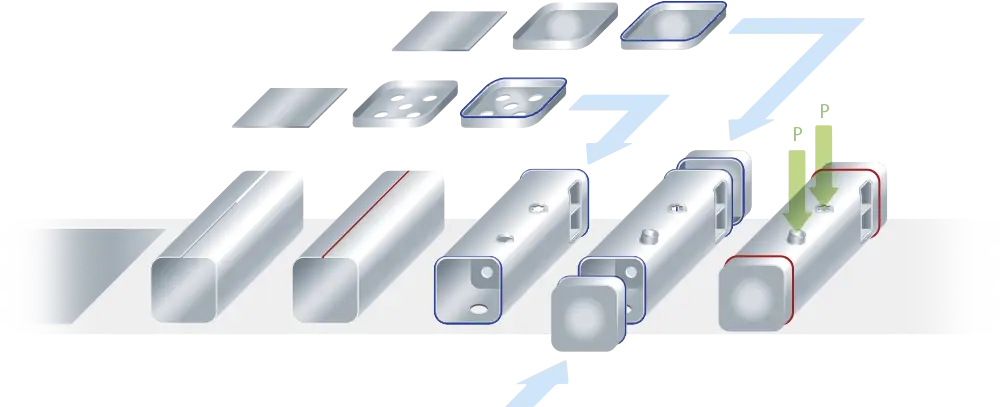

Prefabrication of end caps and baffles:

- Deep-drawing

- Edge processing, beading and trimming

Prefabrication of shells:

- Bending

- Longitudinal seam welding

- Punching and forming for filler neck, level sensor and drain area

- Beading of shell segments, e.g. for footstep segments

- Pressing of baffles into shells and clinching or welding

Assembly:

- Joining of end caps and shells

- General welding

- Welding of add-on parts

Leak testing

Producion plants for fuel tanks for commercial vehicles

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information