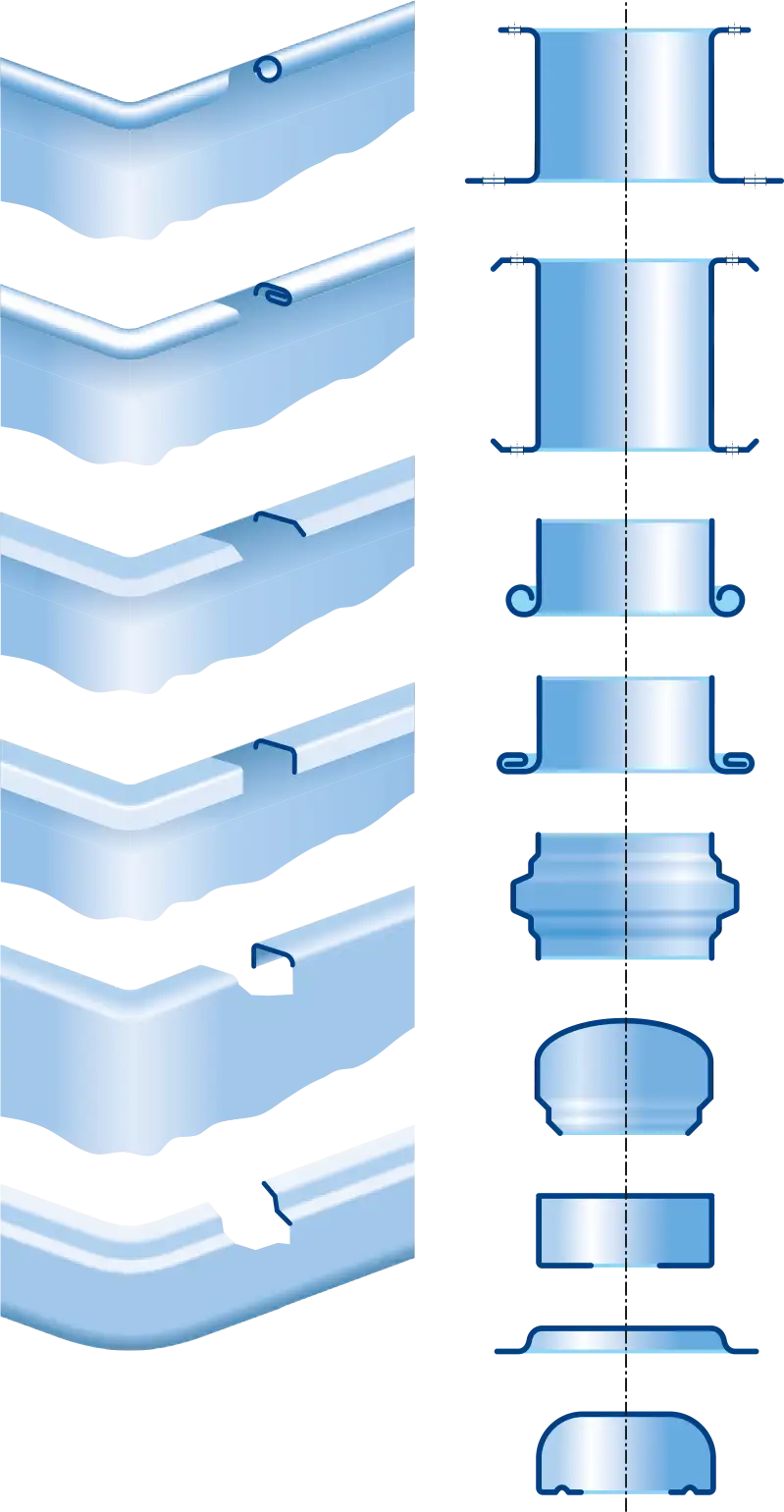

Modular machines for drawn parts, spun parts and tubes

Trimming and forming hollow sheet metal parts

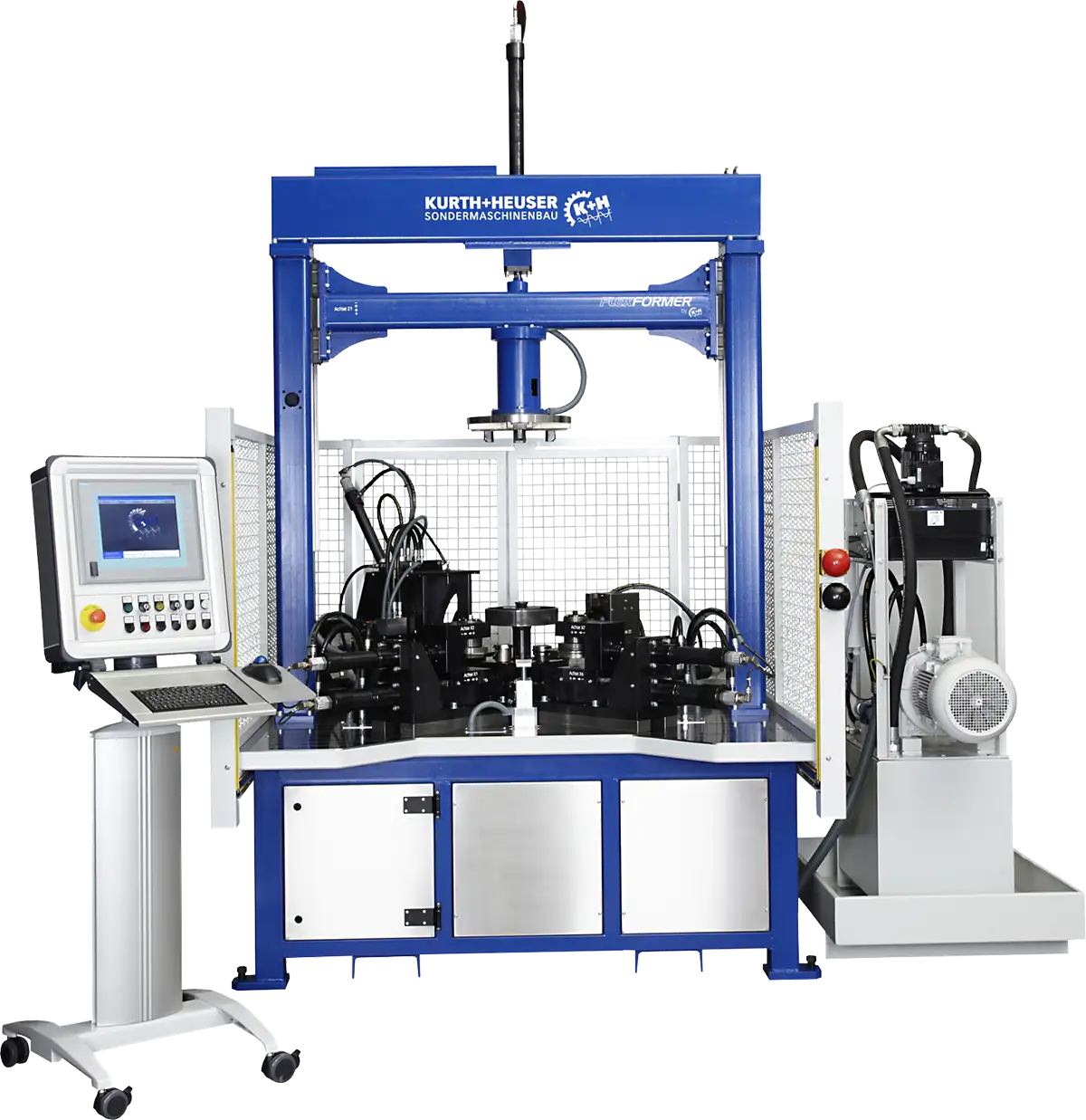

The concept

Machines by KURTH + HEUSER have a modular design. This allows a flexible setup using the right processing units and a custom adaptation for many workpiece geometries and tasks.

The machines always offer optimum economic efficiency and flexibility along with perfect ergonomics and safety for the operator. Conversion to new production tasks is quick and easy. Setup times can be significantly reduced by innovative solutions such as servo-hydraulic standardised drives.

Highlights

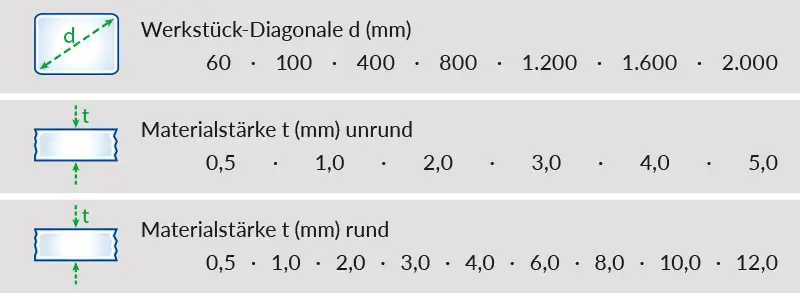

- Economical for circular and non-circular workpieces

- Safe and ergonomic operation

- Flexible processing units

- Exact scaling

- Modular machine design

The performance profile

- Up to 5 processing units working simultaneously on one basic machine

- Speed-controlled drive spindle – also for circular and non-circular operation

- Servo-hydraulic, servo-electric, hydraulic or pneumatic tool drive

- Conventional or fully flexible control

- Ergonomic control panel for optimal operator convenience

- Short machine setup times thanks to easy adjustment of processing units

- Compact design with machine, hydraulic unit and control cabinet as one unit

- Proven safety concept

- Remote diagnostics via LAN, WLAN or GSM

- Hands-on technical documentation in accordance with CE

- Worldwide service through qualified and specialised personnel

Edge processing machines – modular by KURTH + HEUSER

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information