Highly dynamic edge processing

Forming and trimming non-circular hollow sheet metal parts

The concept

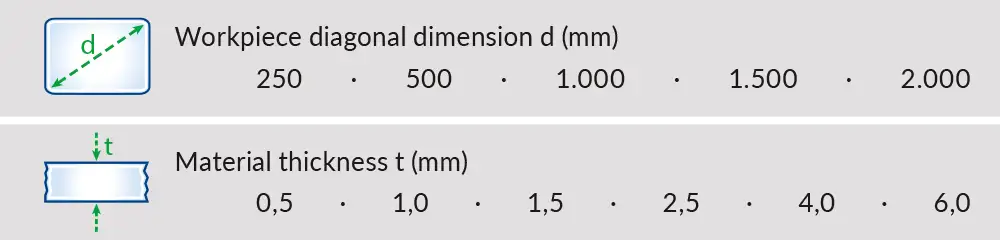

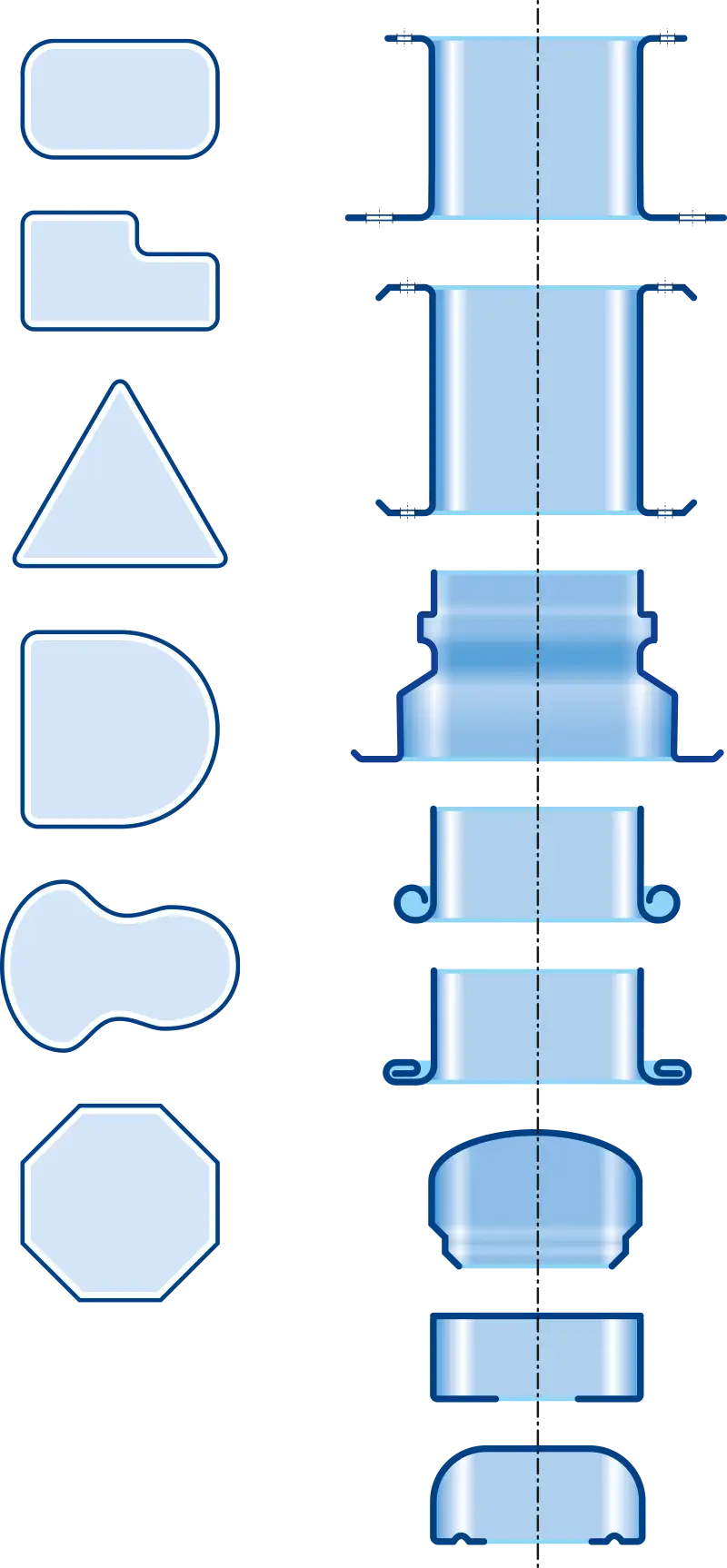

With the EASYFORMER line, KURTH + HEUSER presents its innovative edge processing machines for the production of non-circular sheet metal hollow parts and blanks with different geometries. The machines offer extraordinary flexibility for the processing of various workpiece contours, materials and sheet thicknesses.

Highlights

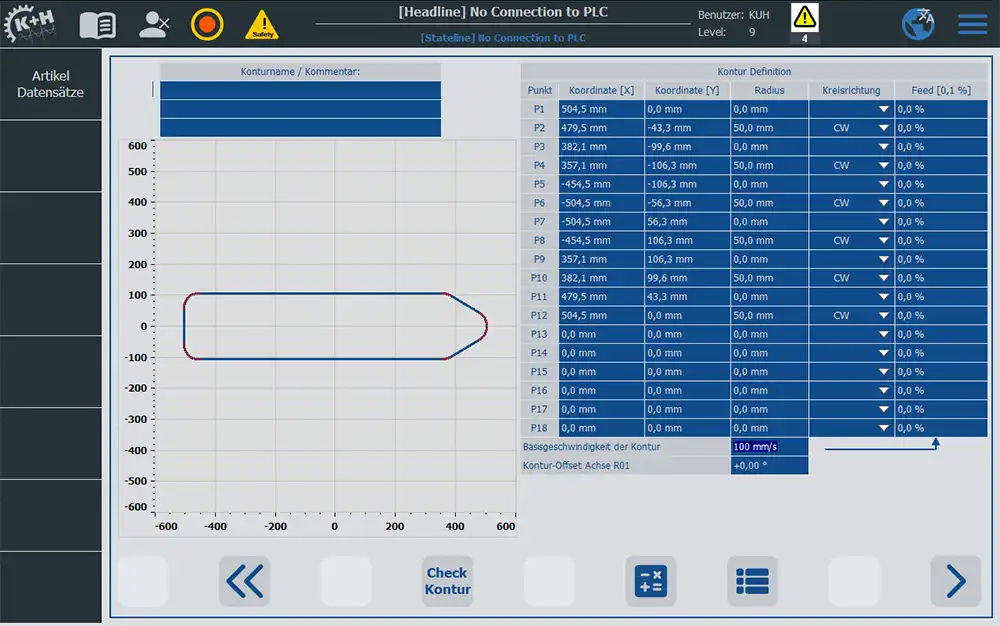

- Easy programming for the workpiece contours (no mechanical copy plate required)

- Servo-electrical work spindle with dynamic speed control

- Servo-hydraulic axes – robust and accurate

- 60 % less tooling costs

- 80 % less setup time and setup errors

- 80 % less wear

- Flexible programming

- Perfect repeat accuracy

The technology

Highly dynamic operation, accurate positioning, excellent repeat accuracy as well as robustness and long service life were the requirements set for the development of the EASYFORMER line. The result is the accurate interaction of servo-hydraulic actuators with a servo-electric workpiece drive, controlled by the EASYFORMER control for maximum precision.

Programming by operators

Machines of the EASYFORMER line are easily set up even by operators without professional training: The workpiece contour is parameterised via a graphical programming interface. This makes it possible to set up desired contours quickly. Highly dynamic EASYFORMER actuators ensure the precise implementation even of non-standard edge geometries on non-circular workpieces. Material deviations of the workpiece can be compensated swiftly and flexibly by adjusting the program.

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information