The benchmark for preparing joining edges of vessel heads

Flexibly scaled production solutions to process joining edges (weld edges)

High forming forces, accurate positioning

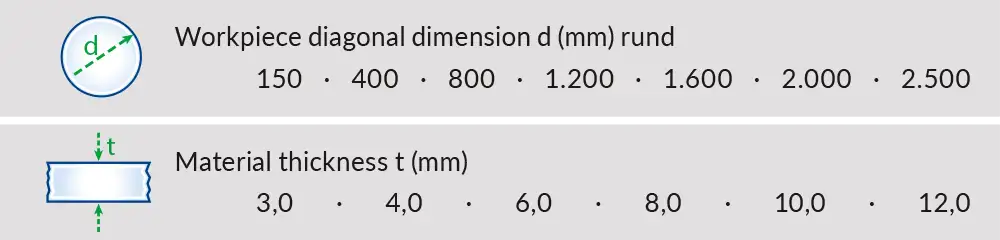

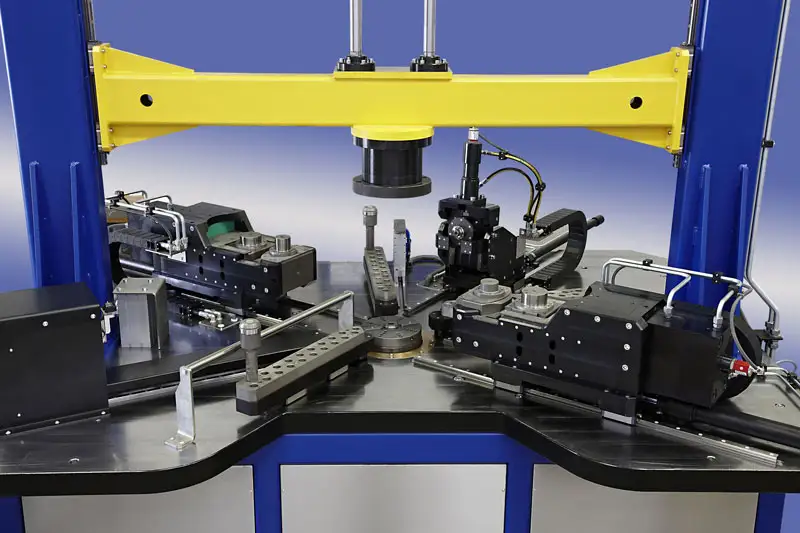

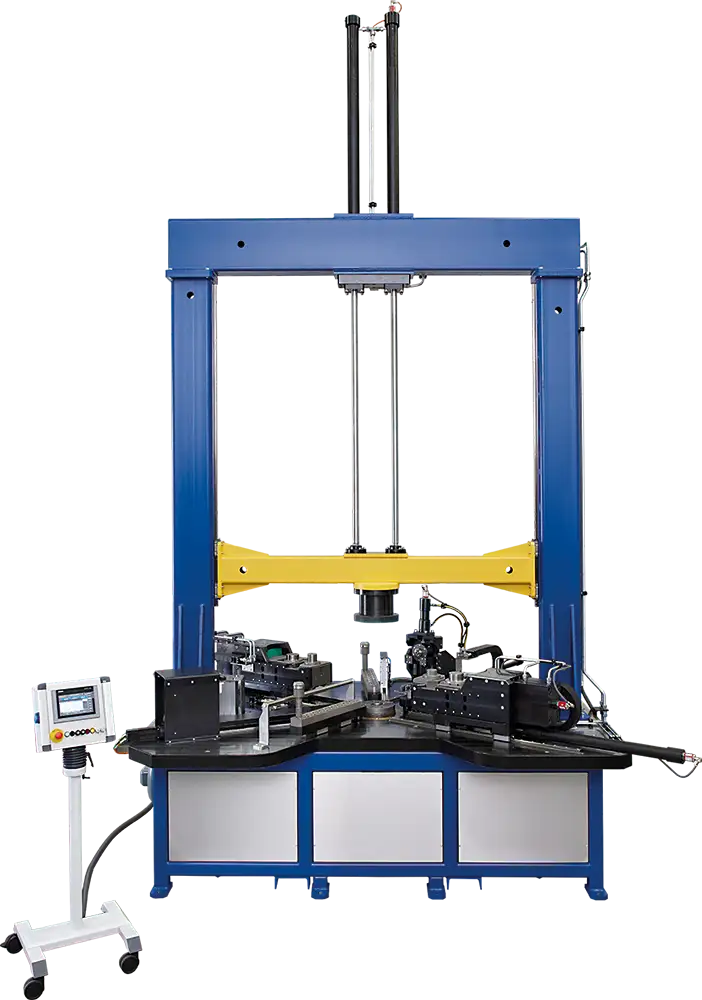

With its POWERFORMER, KURTH + HEUSER presents an innovative line of machines for the edge forming of vessel heads with torispherical, semi-ellipsoidal, elliptical and other geometries. The special feature of these machines is the combination of the proven servo-hydraulic axes with the securely guided high forming force of up to 24 t. The freely programmable, servo-hydraulic vertical adjustment of workpiece fixtures and clamps allows the POWERFORMER to be used flexibly and effectively. A generously dimensioned block guidance of the actuators ensures a high level of availability, quality and repeat accuracy.

Highlights

- Servo-hydraulic or servo-electric axes: robust and accurate

- Forming forces up to 24 t

- Clamping forces up 15 t – no spreading chuck required

- Universal workpiece centring

- Servo-hydraulic height adjustment of the workpiece fixture

- 80 % less setup time and setup errors

- Flexible programming

- Perfect repeat accuracy

Modular design

Machines of the POWERFORMER line are made up of modular basic machines. In addition to trimming and beading, further actuators are available to execute e.g. the rounding of workpiece edges. A highly accurate circumference measuring system is available as an option to ensure the reliable processing of vessel heads. Fitted with the matching handling system (handling automats, manual systems), the POWERFORMER can be optimally integrated into any existing process chain.

Programming

Machines of the POWERFORMER line are easy to set up thanks to their various input options such as tool diameter and vessel head diameter. The positions of all axes are saved in a workpiece-specific data set. All setting parameters are readily available whenever a product is changed. In conjunction with the servo-hydraulic height adjustment of the workpiece fixture, the set-up time can be reduced by up to 80 %.

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information