Machines and plants for sheet metal processing

From stand-alone machines to complete production lines

Production systems for the edge forming of hollow sheet metal parts

Technology – Innovation – Service

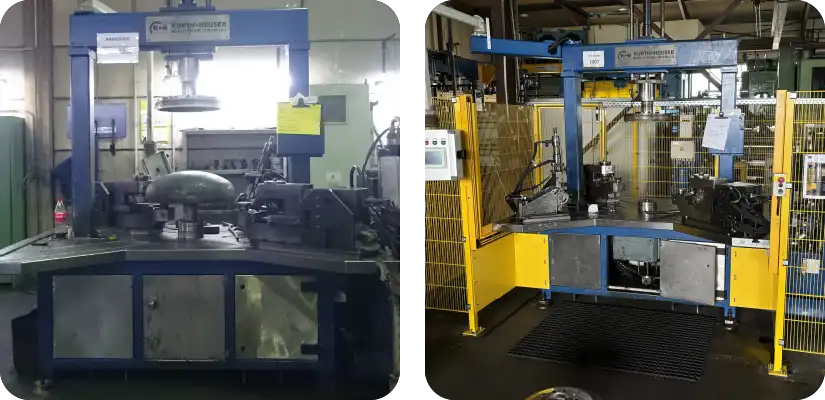

KURTH + HEUSER is a synonym for trimming and edge forming of hollow sheet metal parts: Bending, trimming, edging, flanging, radius forming, rolling, beading, punching and folding are only some of the processing methods we apply. Our methods are suitable for circular and non-circular vessels, spun and drawn parts, tubes and rings made from sheets with diagonal dimensions up to 2.500 mm, a material thickness of up to 12 mm and a length of up to 2.000 mm

KURTH + HEUSER offers a wide range of machines for various tasks:

All products are based on our exceptionally efficient, classic edge processing machines.

Three machine lines are used for frequently changing tasks:

FLEXFORMER machines for circular hollow workpieces feature a fully flexible control system,

EASYFORMER machines for non-circular hollow workpieces are independent of tools and easily programmed,

POWERFORMER machines feature a high forming power for workpieces with high wall thicknesses.

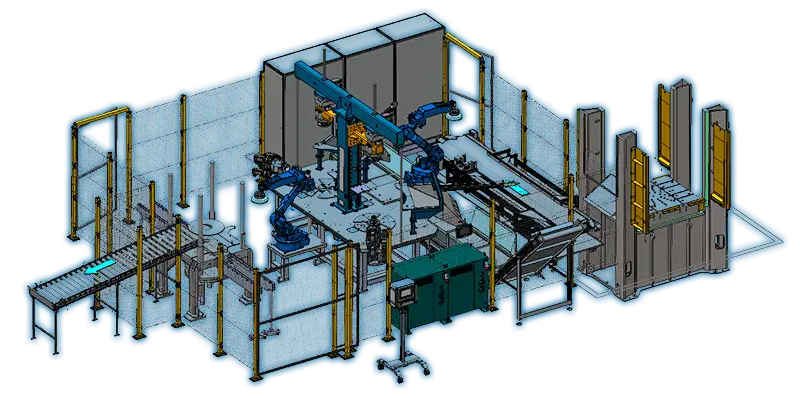

High-performance production lines comprising different individual machines are offered for high-volume production series.

Our products